Compressed Air Light & Power is the exclusive supplier of Atlas Copco products across regional NSW, offering a wide range of 90 products.

Compressed Air Light & Power is the exclusive supplier of Atlas Copco products across regional NSW, offering a wide range of 90 products.

Our range includes:

Generators from 1kva up to 1 megawatt

LED Light Towers

Air Compressors – electric and diesel to 1,500cfm, portable and stationary units

Pumps – diesel and electric

Wide range of self-bunded fuel tanks

We also custom build combination packs for trailers and service trucks to your specification

Compressed Air Light & Power rentals provide a fast, reliable and easy solution to keep your business operating.

Compressed Air Light & Power rentals provide a fast, reliable and easy solution to keep your business operating.

We have an industry leading range of equipment for short and long-term rental, with more than 40 machines available across the range. All rentals are latest models, delivered site and are ready to ‘plug and play.’ Equipment is fully maintained and 100% reliable.

Load testing your generator

Load testing your generator

Generators play very crucial roles in that they provide backup power in moments of power outages. They are however vulnerable to several misfortunes which need actioning in a timely and appropriate manner in case their reliability is to be guaranteed in the long run. As a generator owner or end user, you need to understand the potential problems that

emergency standby generators may encounter and how to mitigate them.

Potential problems of emergency standby generators

The functioning and performance of generators may be affected by several factors that include the following:

- Age

- With time, as generators age, weaknesses are naturally bound to arise. These

weaknesses are mainly caused by the common elements of wear and tear and have

the consequences of compromising the functioning of the generators. - Negative externalities like weather and pests can also affect the efficiency of

generators negatively.

- Wet-stacking; Wet stacking is a phenomenon that occurs whenever generators do not

hit the design temperatures and thus do not burn out all the fuel. This allows Carbon

and unburned fuel to accumulate in the exhaust systems which in turn degrades the

performance of the system by not allowing it to perform as intended. - Some generators are designed with some redundancy on the load for the sake of

future expansion. This means they are naturally inadequately charged to prevent wet

stacking.

Load Test

Generator load evaluations should be carried out in the generator from time to time to identify and mitigate these problems. This may take various forms such as using of building load, monitoring the generator exercise regularly to ensure that it starts and runs as programmed, and the use of a portable load bank.

Importance of Generator Load Tests

Testing generators, just like every other piece of an electrical appliance is a very significant undertaking. The following are some of the main reasons why this is so:

Ensure Reliable Performance

Testing the generator under load ensures that it performs as designed and when it is needed most. That is because generator load tests allow for the verification of the generator system to ensure that it produces and maintains full load without either overheating or shutting

down.

Ascertain the State of the Various Components

Through this test, it is possible to ascertain the various components of the generator system to ascertain that they all worked interdependently as designed and intended to achieve a common goal. It also allows for the detection and identification of potential weaknesses in controlled conditions.

Enables Proactive Maintenance

Load testing allows for proactive maintenance i.e. helps in the identification of any potential weaknesses beforehand in controlled conditions, unlike in moments of utility outage when weaknesses may cause a complete failure of the system.

As a general rule, it is recommended that all diesel engines be load-tested using a portable generator load bank for at least two hours annually. In cases the engine has not been tested for at least a year, then longer tests may be needed.

What next?

In conjunction with your preferred electrician, our team of trained technicians has the wherewithal to implement a load testing scenario. We will also ensure that the plan is carried out professionally and that any issues that may arise are brought to your attention timely to

ensure that you are adequately prepared for any future interruptions in utility power supply.

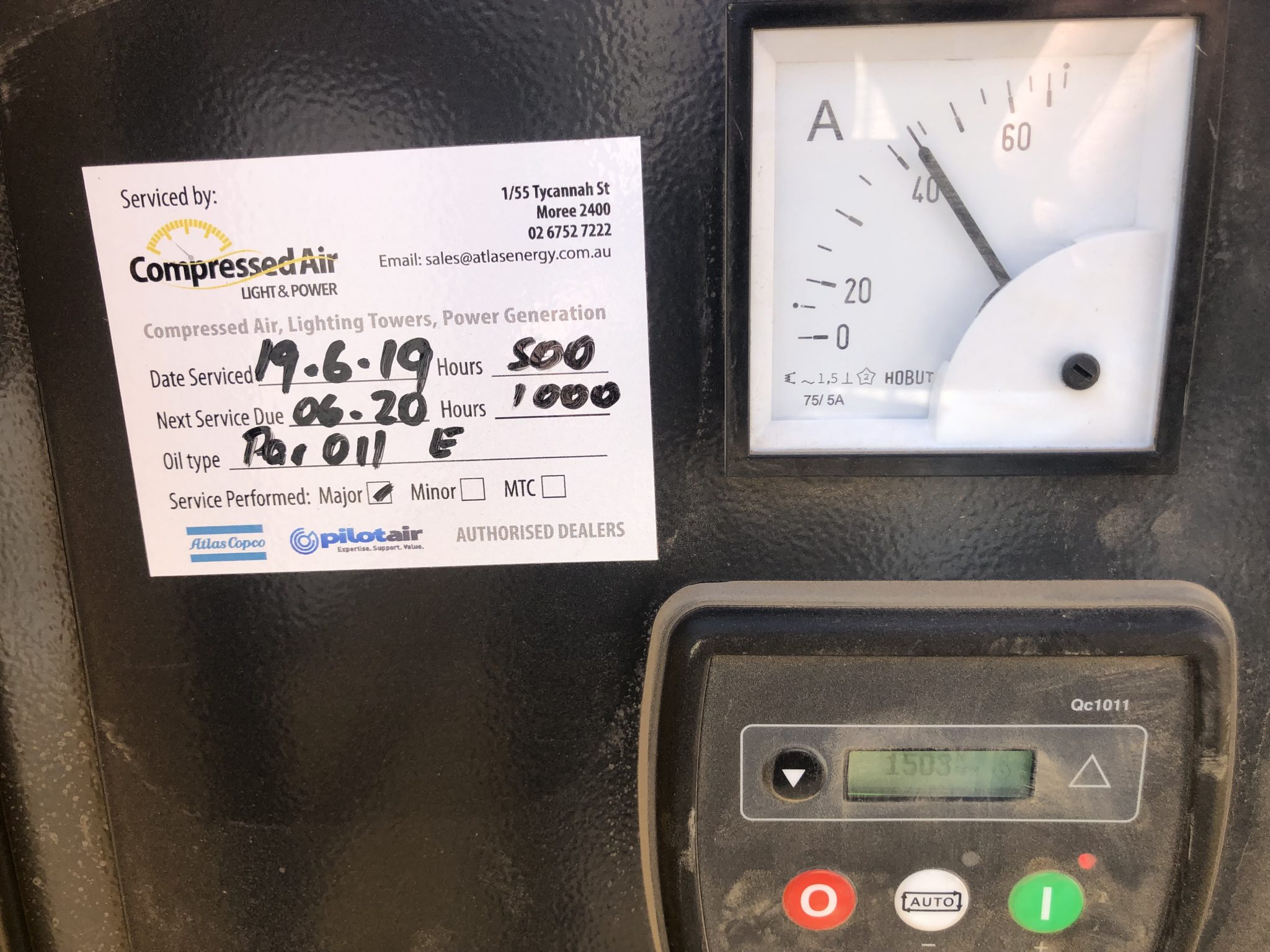

Working hands-on with our clients over more than 10 years, Compressed Air Light & Power has a high level of expertise in maintaining Atlas Copco equipment.

Working hands-on with our clients over more than 10 years, Compressed Air Light & Power has a high level of expertise in maintaining Atlas Copco equipment.

We understand that down-time is expensive, so our fully trained and authorised service team get it right the first time, to eliminate re-work, keeping your machine working and yourbusiness operational to maintain business momentum. Compressed Air Light & Power offer rapid response, as soon as we can service.